Ultrasonic Flow sensor

Application: It's used in the Calorimeter

Ultrasonic flow sensor for continuous measurement in industrial environments contain large concentrations of suspended particles or gases most clean uniform liquid flow and heat. It is the use of ultrasonic wave propagation in the fluid flow , the flow along the reverse flow velocity and the propagation speed difference calculating propagation velocity of the fluid to calculate the fluid flow . No special requirements for the media ; flow measurement accuracy is not affected by the measured fluid temperature, pressure , density and other parameters.

Operating principle:

Ultrasonic flow sensor consists of ultrasonic transducers, electronic circuits and accumulated flow display and a three-part system. Ultrasonic transmitting transducer converts electrical energy into ultrasonic energy, and emitted into the fluid to be measured, the receiver receives the ultrasonic signal, is amplified and converted by the electronic circuit is supplied to an electric signal representative of the flow meter display and display totalizer and totalizer. This realization of the traffic detection and display. According detection methods can be divided into propagation velocity difference method, the Doppler method, the beam offset method, noise law and related laws, such as different types of ultrasonic flow sensors. Ultrasonic flow sensor is a past ten years with the rapid development of integrated circuit technology began to applications.

Main feature:

- launch crystal ultrasonic flow sensor in direct contact with the liquid being measured, improves the accuracy and stability of the machine's operation.

- solve the pipe wall due to severe fouling or corrosion when using external tie sensor signal is weak, the measurement problem is not normal; cement pipes can be installed in the road (should know the actual diameter of the pipe to the factory-made pipe clamps).

- to solve due to the prolonged use of clamp-on sensor, resulting in a dry coupling agent can not affect the normal transmission of ultrasonic signals, does not work and other issues.

4、the relative electromagnetic flowmeter for use on large-diameter pipe economical and reliable and accurate.

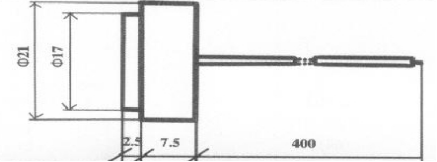

1. Model: FT-TS17A

Central Frequency |

withstand voltage |

Size of mounting surface |

970±30KHz |

4.5MPa |

Ф21mm |

Static capacitance |

Launch beam Angle |

Method of encapsulation |

600PF±20% |

5º-10º |

epoxy resin |

Resonance impedance |

Sensitivity of receiving |

Position of lead |

<110Ω |

>200mv |

Central of sensor |

Protection glass |

Material of shell |

Type of the wire |

IP68 |

Combination cuprum&plastic |

Ф2.5mm coaxial wire |

Operating temperature |

Size of emitting surface |

Length of lead |

<100℃ |

Ф17mm |

400mm |

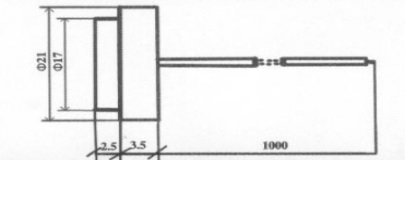

2. Model: FT-T17A

Central Frequency |

withstand voltage |

Size of mounting surface |

970±30KHz |

4.5MPa |

Ф21mm |

Static capacitance |

Launch beam Angle |

Method of encapsulation |

600PF±20% |

5º-10º |

epoxy resin |

Resonance impedance |

Sensitivity of receiving |

Position of lead |

<110Ω |

>200mv |

Central of sensor |

Protection glass |

Material of shell |

Type of the wire |

IP68 |

100% copper |

Four-core double-shielded |

Operating temperature |

Size of emitting surface |

Length of lead |

<100℃ |

Ф17mm |

1000mm |

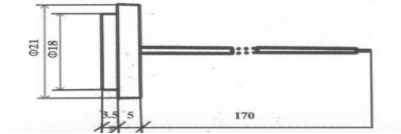

3. Model: FT-18C

Central Frequency |

withstand voltage |

Size of mounting surface |

970±30KHz |

>3MPa |

Ф21mm |

Static capacitance |

Launch beam Angle |

Method of encapsulation |

500PF±20% |

5º-10º |

epoxy resin |

Resonance impedance |

Sensitivity of receiving |

Position of lead |

<110Ω |

>300mv |

Central of sensor |

Protection glass |

Material of shell |

Type of the wire |

IP68 |

High polymer material and stainless steel nut |

Ф1.7mm high frequency coaxial wire |

Operating temperature |

Size of emitting surface |

Length of lead |

<100℃ |

Ф18mm |

170mm |

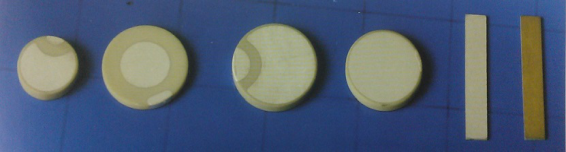

The Piezoceramic Elements for Ultrasonic flow sensor

Spec. (mm) |

Parameter |

|||

Frequency (KHz) |

Capacitance (±20 pF) |

Temperature Max (°C) |

Pressure Max (MPa) |

|

OD40.0x2.0 |

1000±30 |

8000 |

150 |

2.56 |

OD40.0x4.0 |

500±15 |

4000 |

150 |

2.56 |

OD25.0X2.0 |

1000±30 |

3000 |

150 |

2.56 |

OD20.0x4.0 |

500±15 |

600 |

150 |

2.56 |

OD20.0x2.0 |

1000±3 |

1100 |

150 |

2.56 |

OD16.0x2.0 |

1000±30 |

1000 |

150 |

2.56 |

OD16.0x2.0 |

1000±30 |

500 |

150 |

2.56 |

OD15.0x2.0 |

1000±30 |

1000 |

150 |

2.56 |

OD14.0x2.0 |

1000±30 |

950 |

150 |

2.56 |

OD14.0x2.0 |

1000±30 |

500 |

150 |

2.56 |

OD14.0x1.5 |

1400±40 |

650 |

150 |

2.56 |

OD13.5x2.0 |

1000±30 |

950 |

150 |

2.56 |

OD12.0x2.0 |

1000±30 |

800 |

150 |

2.56 |

OD11.0x2.0 |

1000±30 |

600 |

150 |

2.56 |

OD10.0x2.0 |

1000±30 |

400 |

150 |

2.56 |

OD8.0x2.0 |

1000±30 |

300 |

150 |

2.56 |

23.0x4.xx0.5 |

|

2300 |

150 |

|

23.0x4.0x0.5 |

|

2300 |

280 |

|

*Our customers can customize a variety of models with ceramic of ultrasonic sensor and sensor.

Tel: +86-21-64384700 email: info@sinocera.net